How To Make Cinnamon Incense – The Most Basic And Detailed Instructions

Since ancient times, each incense stick has become a cultural beauty of Vietnamese people. So, have you ever asked the question how to make incense ? What materials are incense made from, is the process to produce incense simple or complicated? Read the article below to answer those questions!

How to make incense - main ingredients and ingredients

To create incense sticks, incense needs a lot of ingredients combined. Some ingredients can be used to make incense such as:

- Litsea bark powder: this is the ingredient that helps to create a binder. Accordingly, in the bark of this tree there is a glue-like substance.

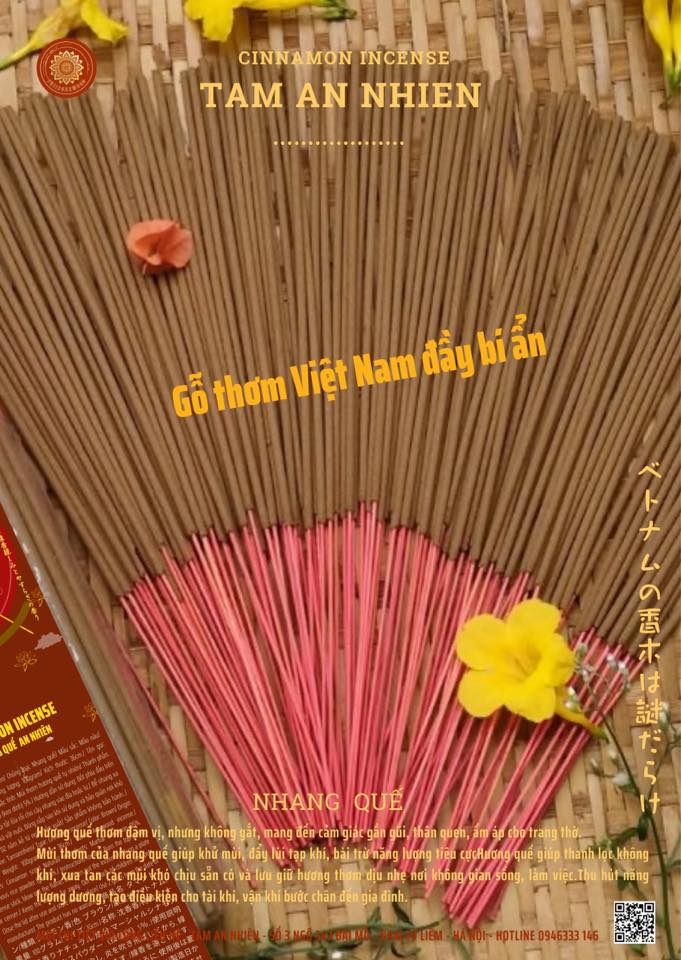

- Wood powder: can use wood pulp of agarwood, cinnamon, eucalyptus. Depending on the type of incense you want to make, you can choose the appropriate powder. In particular, cinnamon incense is made from cinnamon wood powder, has a characteristic cinnamon aroma. Cinnamon incense is made from wood pulp cinnamon tree, has a light fragrance, long deposition. This type of incense has a high price because cinnamon is a valuable tree, so products made from this tree are also expensive. Eucalyptus incense is a type of incense made from eucalyptus wood pulp, also known as eucalyptus tree, which can be easily found anywhere.

- Some herbs: traditional medicine, roots of incense, herbs, herbs...

- Trees used to make incense sticks, all kinds of bamboo

How to make incense - basic steps

The production process of incense is very complicated and elaborate. To ensure the quality and safety when using the clean incense requires strict stages.

Step 1: Check the source of input materials

For the best fragrance. Before putting it into the blender, we need to select, classify the ingredients and remove the impurities carefully. If the impurities are not removed, the scent of cinnamon will be changed or even lost the smell of cinnamon.

Step 2: Proceed to grind and grind into powder from raw materials

The blender will grind the ground cinnamon or cinnamon flakes and grind them into a powder. The incense maker needs experience to adjust the grinding intensity and grinding time. Besides, the meticulous, careful and the support of modern machinery can obtain the maximum smooth double incense powder. The finer the powder, the higher the quality of the finished product.

Step 3: Sift cinnamon powder until smooth and mix well with binder (vegetable glue)

In order to produce a quality and beautiful product, it is very important to screen the ground powder in step 2. This sifting will help obtain a highly fine cinnamon powder. The sifting of flour is also very easy, can be done by specialized machinery systems.

The finely ground cinnamon powder will be mixed with a vegetable glue binder - which is the pulp of the Litsea tree. This is a powder to produce clean incense, creating an adhesive like glue without affecting the health and aroma of the product during use. Depending on the product line of incense, the mixing ratio between cinnamon powder and Litsea powder is different.

Add water to this mixture to form a binder. This is a very important stage, a big decision to the scent of incense. Normally, high-quality incense sticks are mixed with the ratio: cinnamon powder (premium type 1 type 2): 95% and the amount of adhesive: 5%. Do not mix any other chemicals or ingredients.

Put the mixed flour mixture into a specialized machine to create the product. Incense powder is a very fragile powder, the maker needs to be careful at this stage to avoid encountering cases such as unscented incense, cracked incense or unburnt incense...

Step 4: Dry the incense in the sun

For clean cinnamon incense to have the best finished product, incense needs to be dried in natural conditions. Incense can be dried in sunlight or dried.

Especially with cinnamon incense made from cinnamon powder, incense makers need to pay attention to weather conditions. In particular, it is necessary to pay attention to the sun and wind need to be just enough to help the incense after drying have a beautiful shape, not warping. This is also a very important factor constituting product quality besides choosing input materials.

Step 5: Dehumidify the product

The dehumidifying room is where the incense is put in after it dries naturally. This helps the incense to remove the maximum amount of mold. Make sure the incense can burn, reduce the amount of steam, and be usable.

Step 6: Check the quality, warping of incense and packaging

Standard incense needs to be straight, not crooked, moldy… Pack and store incense in a dry place.

Above is the most common and common process of making cinnamon incense. Different types of incense will have different methods and standards, but the basic steps are almost the same. Hopefully this article has helped you understand how to make incense and see the meticulous care of the craftsmen.

FUJI INTERNATIONAL TRADING IMPORT EXPORT JOINT STOCK COMPANY

Add: Số 3/347 Dai Mo - Nam Tu Liem – Ha Noi

Tell / Hotline/ Zalo : 0967767617

Email : sougouagarwood@fujinetwork.com.vn

Website: http://fujiagarwood.com

Facebook Fanpage : https://www.facebook.com/tamannhienagarwood